Hydraulic slurry pumps have become indispensable across mining, oil and gas, municipal infrastructure, and heavy industries, where the demand for reliable slurry transport continues to grow. Designed to handle abrasive, viscous, and solids-heavy fluids, these pumps address some of the toughest challenges in modern operations, ensuring efficiency, durability, and cost control. By combining solid engineering with high-performance capabilities, hydraulic slurry pumps provide a major advantage in projects where traditional pumping systems often fall short.

Unlike conventional pumping equipment, hydraulic slurry pumps are specifically engineered to handle high concentrations of solids without rapid wear or loss of performance. Their ability to maintain continuous flow under extreme conditions makes them essential for industries that rely on uninterrupted operations.

As global projects grow in scale and complexity, leaders are increasingly seeking innovations that deliver measurable returns on investment. Upgrades in pump materials and the integration of smart monitoring technologies are not just improving durability; they are transforming how hydraulic slurry pumps support long-term project efficiency, reducing downtime, and ensuring compliance with environmental and operational standards.

Understanding Hydraulic Slurry Pumps

Operating Principle

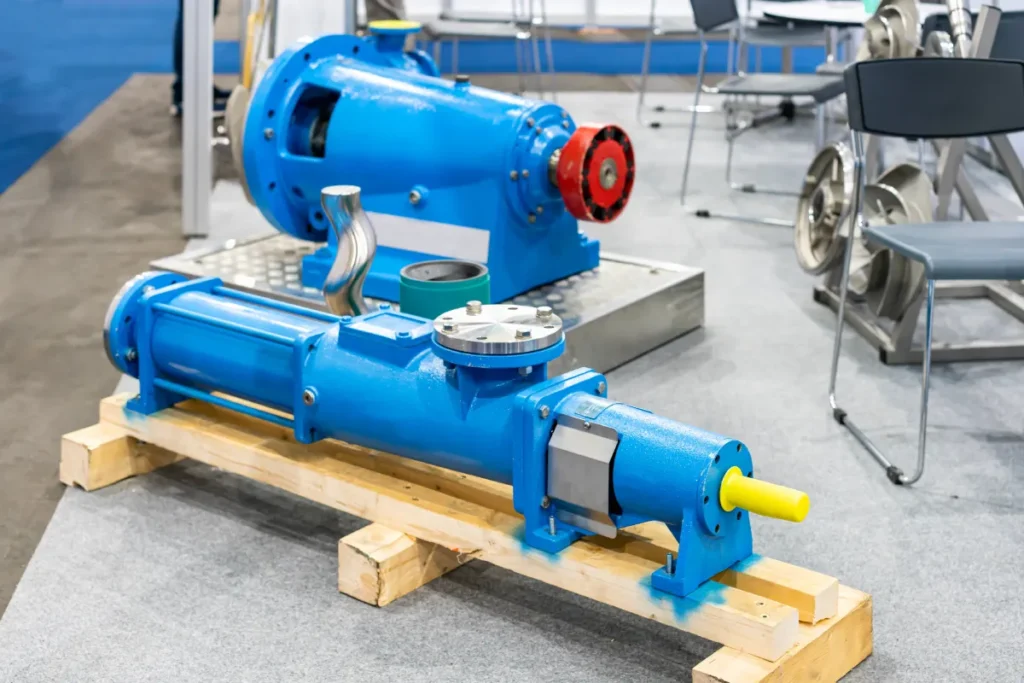

Hydraulic slurry pumps operate on the centrifugal principle, where a rotating impeller accelerates a mixture of fluid and suspended solids (slurry). This process converts kinetic energy into flow and pressure, enabling the pump to move abrasive mixtures efficiently. Their sturdy design, combined with a hydraulic drive, provides enhanced flexibility, particularly in demanding applications that require variable flow control.

Types and Variations

- Hydraulic Submersible Slurry Pump

A hydraulic submersible slurry pump is designed for submerged operations, making it highly effective in environments where electric motors are impractical or unsafe. By using hydraulic power instead of electricity, these pumps provide superior reliability in confined spaces, underwater conditions, or hazardous environments. Industries from mining to municipal wastewater rely on the hydraulic submersible slurry pump for its portability, safety, and capacity to handle high-solid concentrations directly at the source. - Dredge Slurry Pump Hydraulic Systems

For large-scale sediment removal, reclamation, and tailings transport, dredge slurry pump hydraulic systems are the preferred solution. These heavy-duty units combine the force of hydraulics with abrasion-resistant materials to tackle some of the toughest dredging and tailings challenges. Contractors often opt for dredge slurry pump hydraulic configurations for offshore dredging, mining tailings ponds, and harbor maintenance, where extended run times and continuous high-volume pumping are necessary.

Applications Across Industries

The flexibility of hydraulic slurry pumps allows them to serve a wide range of sectors. In dredging, they enable efficient removal of silt and sediment to maintain navigable waterways. In mining, they are deployed to transport abrasive tailings across long distances, minimizing manual handling and operational risks. Municipalities integrate hydraulic slurry pumps into wastewater facilities to manage sludge, grit, and other solids that conventional pumps cannot handle. Military and naval operations rely on dredge slurry pump hydraulic systems and hydraulic submersible slurry pumps for rapid-response dewatering, coastal maintenance, and disaster recovery tasks.

By combining hydraulic power with durable construction, hydraulic slurry pumps continue to demonstrate their role as a cornerstone of modern fluid-handling systems across industries.

Challenges in Traditional Slurry Pumping

Handling abrasive and corrosive slurries has always given serious challenges for pumping systems. While hydraulic slurry pumps have improved reliability compared to conventional models, legacy designs still encounter limitations that affect performance and operating costs.

Abrasive and Corrosive Slurry Compositions

Mining, oil sands, and wastewater slurries often contain high concentrations of sharp, dense particles and corrosive fluids. These challenging conditions significantly increase the risk of wear on pump impellers, casings, and seals. As a result, standard pumps struggle to maintain long-term operation. Without the use of specialized materials, even advanced dredge slurry pump hydraulic units may experience reduced efficiency over time.

High Maintenance and Downtime Costs

Frequent part replacements, routine servicing, and unexpected breakdowns lead to high total ownership costs. This is particularly problematic for industries like dredging or tailings management, where continuous pumping is essential and prolonged downtime can be devastating. For instance, the failure of a hydraulic submersible slurry pump during a confined-space dewatering project can result in significant project overruns.

Limited Lifespan Due to Wear and Material Degradation

Rapid degradation is a common issue for traditional pumps made from standard alloys or untreated metals, particularly when exposed to abrasive or acidic conditions. This significantly reduces their efficiency and service life. Hydraulic slurry pumps in mining operations, for instance, are especially vulnerable due to continuous exposure to coarse tailings, which necessitates superior resistance.

Energy Inefficiency and Lack of Monitoring Capabilities

Older systems often lack smart controls or monitoring features, resulting in higher power consumption and undetected wear. Pumps running at constant speeds waste energy, particularly when flow requirements fluctuate. The absence of real-time data makes it more challenging for operators to manage performance, thereby limiting the full potential of dredge slurry pump hydraulic solutions and hydraulic submersible slurry pumps in demanding projects.

Advanced Materials Transforming Hydraulic Slurry Pumps

The performance of hydraulic slurry pumps is closely tied to the durability of their construction. Recent advances in materials have redefined how these pumps withstand wear, corrosion, and heavy-duty operating cycles. By integrating innovative alloys and composites, manufacturers are extending lifespan, reducing downtime, and lowering total lifecycle costs.

High-Chrome Alloys and Hardened Steels

For environments with extreme abrasion, such as those found in mining tailings and dredging, high-chrome alloys and hardened steels are now the standard. These materials significantly extend the working life of impellers and casings in dredge slurry pump hydraulic systems. Their enhanced hardness resists cutting and grinding effects from sand, gravel, and other solids, making them indispensable in high-wear environments.

Rubber Linings and Polymeric Composites

In conditions where corrosion is more severe than abrasion, rubber linings and engineered composites provide a protective barrier. Many hydraulic submersible slurry pumps now feature rubber-lined casings, which absorb impact from large particles and protect against chemical attack. These linings reduce replacement frequency and improve reliability in municipal wastewater or acidic slurry applications.

HDPE and Composite Materials

Lightweight yet durable, HDPE and fiber-reinforced composites are increasingly being used in hydraulic slurry pumps for both casings and auxiliary piping. Their corrosion resistance makes them ideal for use in offshore dredging or environments with high chemical content. For example, dredge slurry pump hydraulic systems with HDPE components are easier to transport, install, and maintain, providing added flexibility for contractors managing multiple sites.

Case Comparison: Lifecycle Cost Benefits

When compared to conventional metallic pumps, those built with advanced alloys or lined with rubber and composites show a significantly lower total cost of ownership. A hydraulic submersible slurry pump constructed with high-chrome alloys may initially be more expensive. Still, it will outlast standard steel models by several cycles, resulting in savings on replacements and downtime. Similarly, hydraulic slurry pumps with polymeric linings can continue operating in highly corrosive conditions where traditional pumps would require complete rebuilds.

By adopting these material innovations, industries are maximizing the efficiency, resilience, and ROI of both hydraulic slurry pumps and dredge slurry pump hydraulic systems in demanding projects.

Smart Technologies in Hydraulic Slurry Pump Systems

Modern industries are increasingly embracing digital transformation to optimize their operations, and hydraulic slurry pumps are no exception. The integration of smart technologies is reshaping how these pumps are monitored, maintained, and controlled, delivering measurable efficiency and safety benefits.

Embedded Sensors and IoT

Today’s hydraulic slurry pumps often incorporate embedded sensors that track pressure, flow rate, temperature, and component wear in real time. When applied to both dredge slurry pump hydraulic systems and the hydraulic submersible slurry pump, these sensors provide critical visibility into operating conditions that were once hidden. Operators gain the ability to continuously monitor pump health, reducing the risk of unexpected failures in harsh working environments.

Predictive Maintenance with AI/ML

Artificial intelligence and machine learning are now being applied to pump performance data. By analyzing patterns from IoT sensors, predictive maintenance tools can forecast when a part is likely to fail and recommend service before downtime occurs. This approach has been particularly effective for hydraulic slurry pumps in mining and dredging operations, where a single disruption can delay entire projects. Predictive models enable industries to optimize service schedules, ensuring that hydraulic submersible slurry pumps and dredge slurry pump hydraulic units operate at peak efficiency.

Automation & Remote Operation

Automation has given a new definition to safety and productivity. Hydraulic slurry pumps can now be integrated into dredging fleets or large-scale industrial networks, enabling remote operation from centralized control systems. For offshore projects, automation allows dredge slurry pump hydraulic systems to run with minimal human intervention in hazardous zones. Likewise, a hydraulic submersible slurry pump deployed in confined spaces can be monitored and adjusted from a safe distance, reducing risks to personnel.

Energy Optimization

Smart controls such as variable speed drives (VSDs) adapt pump performance to changing flow demands. Instead of running at constant speeds, modern hydraulic slurry pumps adjust output to match site requirements, reducing unnecessary energy consumption. For government buyers and contractors seeking long-term ROI, this innovation lowers operational costs and improves environmental compliance. When applied across fleets of hydraulic submersible slurry pumps and dredge slurry pump hydraulic systems, the savings are significant.

Benchmarking Innovation: Global Examples

The global slurry pump market demonstrates how innovation in scale, materials, and smart integration is setting new standards for efficiency and durability.

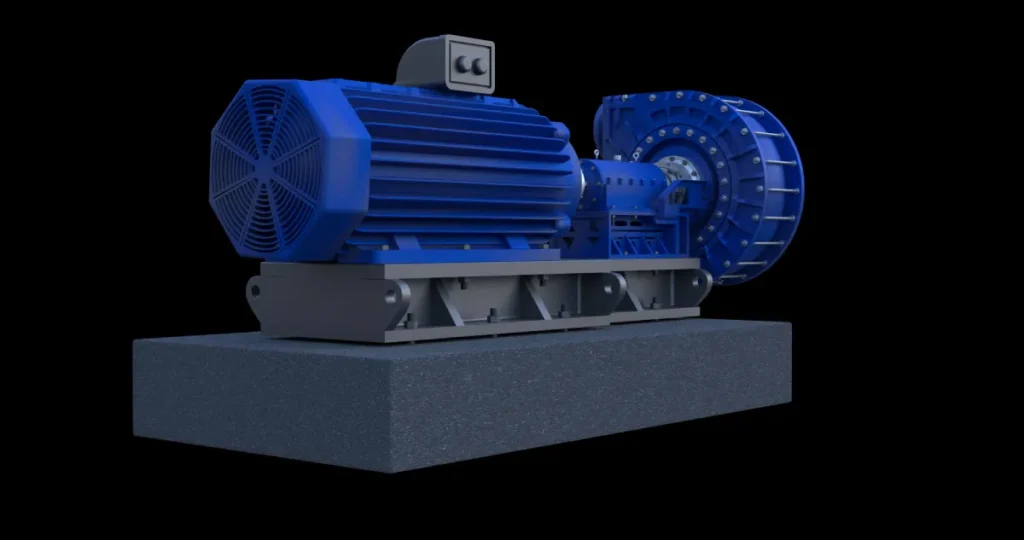

The GIW® TBC-92: Record-Breaking Scale

A milestone in engineering, the GIW® TBC-92 is recognized as the largest slurry pump, operating in Canada’s oil sands. With a 92-inch impeller and a total weight exceeding 200,000 pounds, this pump highlights the capacity of hydraulic slurry pumps to manage extreme volumes of abrasive slurry. Its performance benchmark reinforces why heavy industries increasingly rely on large-scale dredge slurry pump hydraulic systems for demanding projects.

Indian Manufacturers Advancing Submersible Technologies

India’s pump industry has embraced innovation in both design and materials. JB Pumps India Pvt. Ltd. specializes in high-efficiency hydraulic submersible slurry pumps equipped with anti-clogging features. Vikas Pump and Darling Pumps, with decades of expertise, supply a wide range of hydraulic slurry pumps adapted for industrial and municipal use. Their adoption of wear-resistant alloys and modular builds demonstrates how regional manufacturers are aligning with global demand for advanced dredge slurry pump hydraulic equipment.

Emerging Trends in Hybrid Configurations

Across offshore, municipal, and defense applications, hybrid systems combining hydraulic and electric power are gaining traction. These setups enhance flexibility, allowing operators to leverage hydraulic power for high-abrasion tasks while using electric components for energy efficiency. In projects that deploy hydraulic submersible slurry pumps in coastal environments or dredge slurry pump hydraulic fleets for municipal dredging, hybrid technology offers both performance strength and reduced emissions.

Together, these global examples illustrate how hydraulic slurry pumps are not only evolving in scale but also in intelligence, efficiency, and adaptability.

The Future of Hydraulic Slurry Pumps

The future of slurry pumping is being defined by digital integration, sustainable engineering, and modular system design. These advancements aim to deliver equipment that is not only more durable but also smarter and easier to deploy across industries.

Smarter Integration with Industrial IoT Ecosystems

Pumps are increasingly expected to operate as part of connected networks. By linking to industrial IoT platforms, operators can monitor performance across entire fleets, detect issues early, and adjust operations remotely. This type of integration enhances efficiency and safety, particularly in large-scale mining, dredging, and municipal projects.

Advances in Recyclable and Sustainable Materials

Sustainability is becoming a priority in pump design. Manufacturers are adopting recyclable composites and low-impact materials that improve durability while reducing environmental impact. These innovations are especially important for sectors that must balance heavy-duty performance with compliance with environmental regulations.

Modular, Plug-and-Play Pump Systems

Rapid deployment is increasingly critical for contractors and government agencies. Modular pump systems are designed for quick installation, removal, and reconfiguration, enabling teams to adapt to diverse project requirements. This flexibility is particularly valuable in time-sensitive operations such as emergency dewatering or coastal maintenance.

Greater Customization for Specific Industries

Different industries face very different challenges, from the abrasion of mining tailings to the corrosive environments of wastewater treatment plants. Future slurry pumps will be designed with application-specific features, ensuring each sector receives equipment tailored to its unique needs.

Strategic Outlook and Final Considerations

Slurry pumps play a significant role in heavy industries. They’re the powerhouses that shift all those tough, abrasive, and solids-packed mixes. In these demanding settings, you really need pumps you can rely on, and the latest engineering advancements are delivering exactly that. The newest pumps combine super-tough materials with smart technology to significantly enhance their reliability and efficiency.

Slurry pumps are evolving to meet increasingly complex demands across various sectors, including mining tailings management, large-scale dredging, wastewater treatment, and defense. The integration of advanced materials and smart digital technologies drives this advancement. For industry leaders, these innovations result in reduced downtime, lower operational costs, and improved compliance with environmental and safety standards.

When considering future investments, organizations should look beyond immediate project requirements. Long-term value will be determined by the capacity to integrate pumps into wider IoT ecosystems, quickly implement modular systems, and meet sustainability goals.Celtic Pumps & Dredges is positioned as a trusted partner in this transition. By delivering solutions that combine proven durability with forward-looking innovation, the company ensures its clients gain access to equipment that not only performs today but also anticipates the challenges of tomorrow.