Dredging and slurry transport play a vital role across industrial and marine sectors, supporting critical operations such as port maintenance, mining tailings management, land reclamation, and waste recovery. These processes involve moving large volumes of sediment, silt, and abrasive materials, requiring equipment that can perform consistently in demanding environments. Traditionally, diesel-powered systems have dominated the market due to their mobility and power output. However, as industries face stricter environmental regulations and rising operational costs, the limitations of fuel-based systems—high emissions, frequent maintenance, and variable efficiency—have become increasingly apparent.

In response, many organizations are shifting toward cleaner and more reliable alternatives. The electric dredge pump has emerged as a major technological step forward, offering energy efficiency, operational precision, and reduced lifecycle costs. Unlike conventional setups, the dredge pump electric design minimizes mechanical complexity while delivering consistent torque and performance, even in heavy-duty applications. This evolution not only enhances productivity but also aligns with global sustainability goals and regulatory compliance standards.

For procurement and project decision-makers, evaluating factors beyond initial investment—such as power efficiency, maintenance intervals, and total cost of ownership—has become crucial. While the electric dredge pump price may vary based on capacity and configuration, its long-term economic and environmental advantages are proving to be a decisive factor for industries aiming to modernize dredging and slurry transport operations.

Understanding the Electric Dredge Pump: How It Works and Where It Excels

An electric dredge pump operates on a straightforward yet highly efficient principle: converting electrical energy into mechanical energy to move dense slurry or sediment-laden fluids. Unlike diesel-hydraulic systems that rely on multiple mechanical linkages and hydraulic lines to transfer power, an electric-driven system uses a direct motor-to-impeller connection. This design eliminates intermediate components, reducing energy loss and ensuring smoother, more consistent performance. The result is a pump that delivers higher efficiency, greater control, and lower overall wear—especially critical in continuous dredging or slurry transport operations.

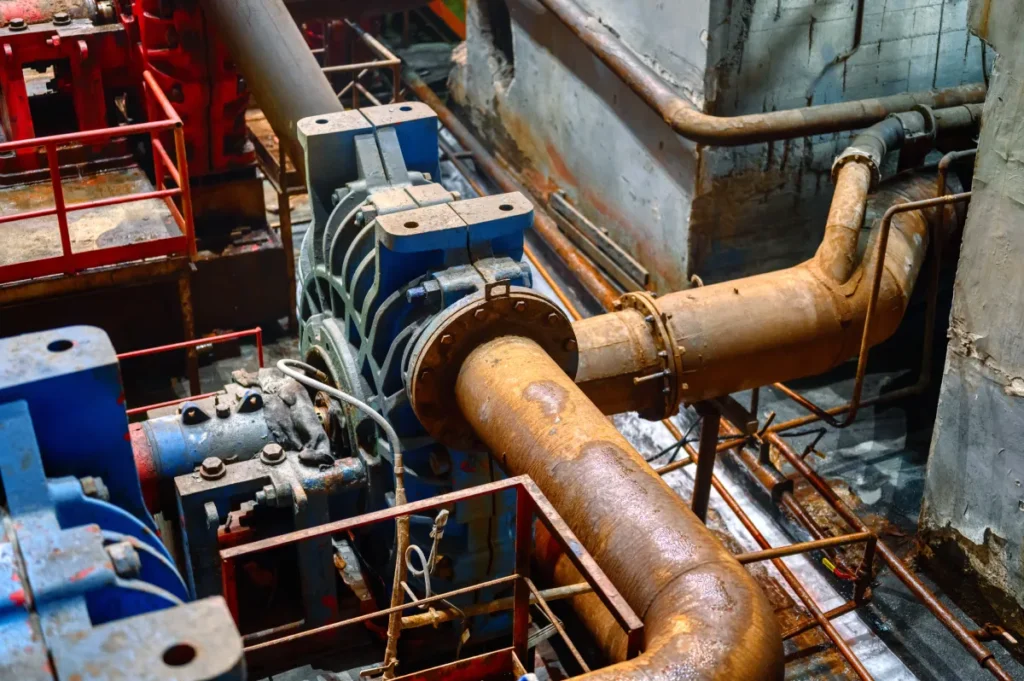

The core components of a dredge pump electric system include a robust electric motor, a high-efficiency impeller, a wear-resistant casing, and a control panel with variable frequency drive (VFD) capabilities. The motor provides steady torque, driving the impeller to generate the necessary suction and discharge pressure. The wear-resistant casing—often made from high-chrome alloys or hardened materials—protects against abrasion from sand, silt, or gravel. The integrated control system allows operators to precisely adjust speed and flow parameters, optimizing performance for varying slurry densities and depths.

Electric dredge pumps are widely used across industries such as mining tailings recovery, port and marina maintenance, pond desilting, and offshore slurry transport. Their adaptability and low-maintenance operation make them ideal for both fixed and mobile dredging setups.

When compared to conventional diesel-hydraulic pumps, electric systems demonstrate clear advantages. They operate with higher energy efficiency due to minimal mechanical losses, produce significantly lower noise and emissions, and eliminate the risks associated with fuel handling and exhaust. Moreover, although the electric dredge pump price can be higher initially, the long-term savings in fuel, maintenance, and downtime contribute to a lower total cost of ownership—making electric dredging technology an increasingly preferred choice for modern, sustainable operations.

Core Advantages of Electric Dredge Pumps

The dredge pump electric system delivers a clear advantage in energy efficiency by ensuring direct power transfer from the motor to the impeller, virtually eliminating the mechanical losses common in diesel or hydraulic configurations. This streamlined energy pathway results in consistent output and optimized power utilization, allowing operators to achieve higher throughput with reduced input energy. In large-scale or continuous dredging operations, these savings compound significantly, translating into lower operational expenses and improved return on investment.

A key differentiator of the dredge pump electric design lies in its ability to maintain constant torque and rotational speed, even under variable load conditions. This consistency ensures stable slurry flow, precise dredging depth control, and minimized wear on internal components—all of which contribute to extended equipment lifespan and greater operational reliability.

Another critical advantage is the precision control afforded by modern electronic systems. With integrated variable frequency drives (VFDs) and programmable logic controllers (PLCs), operators can adjust pump speed, pressure, and power consumption in real time. This adaptability allows for smoother operation across changing slurry densities and site conditions, improving overall efficiency while reducing stress on the motor and impeller.

The electric dredge pump also excels in sustainability and workplace safety. Its zero on-site emissions and low noise levels make it compliant with modern environmental regulations and ideal for operations in urban, coastal, or environmentally sensitive zones. The absence of fuel handling and hydraulic fluids eliminates the risk of spills, ensuring safer, cleaner operations for personnel and surrounding ecosystems.

From a maintenance perspective, electric systems require fewer service intervals compared to diesel or hydraulic models. With no engine oil, filters, or fuel injectors to maintain, downtime is minimized and long-term reliability is enhanced. This directly supports the growing preference among industrial operators for equipment that delivers predictable performance with lower lifecycle costs.

When evaluating the electric dredge pump price, decision-makers should consider not just the purchase cost but also the total cost of ownership. Reduced energy use, minimal maintenance, and extended operational life make electric systems a superior investment for long-term productivity. Their combination of power efficiency, environmental compliance, and technological sophistication establishes them as the preferred solution for modern dredging and slurry transport applications.

Economic Perspective: Evaluating Electric Dredge Pump Price and ROI

Understanding the economics behind a dredge pump electric system requires looking beyond the initial purchase cost and examining the full spectrum of performance and lifecycle savings. The overall electric dredge pump price is typically influenced by three major factors: motor capacity, material composition, and the sophistication of the control system. Larger motor capacities naturally drive higher output and energy demand, while the use of premium materials—such as high-chrome alloys or duplex stainless steel—enhances durability against abrasion and corrosion. Meanwhile, advanced control systems with automation or variable frequency drives (VFDs) allow for precise flow regulation, improving operational efficiency and reducing unnecessary power consumption.

Real-world data from industrial and marine dredging projects consistently show how electric systems outperform traditional setups in long-term cost efficiency. Operators have reported up to 20–30% reductions in energy consumption and significant savings on routine maintenance due to fewer moving components and minimal fluid system wear. These reductions directly lower the total cost of ownership (TCO), helping companies recover their investment faster while benefiting from consistent uptime and predictable maintenance intervals.

In continuous operations such as port maintenance, tailings reprocessing, or lagoon dredging, the dredge pump electric model quickly becomes the smarter financial choice. Despite a potentially higher electric dredge pump price upfront, its superior energy economy, reliability, and maintenance advantages create a strong business case for organizations seeking both performance stability and long-term profitability.

Real-World Applications Across Industries

The versatility of an electric dredge pump makes it indispensable across industries where efficiency, reliability, and environmental compliance are critical. In the mining sector, it plays a central role in tailings reprocessing and mineral slurry transport, helping operators recover valuable materials while minimizing waste. Electric systems ensure steady power output and precise control, allowing continuous handling of abrasive slurries with minimal downtime.

In the oil and gas industry, the dredge pump electric configuration supports offshore maintenance dredging and waste recovery operations. Its robust design, sealed components, and corrosion-resistant materials make it ideal for harsh marine environments where safety, uptime, and environmental protection are paramount.

For municipal and naval applications, electric dredging systems are used in harbor cleaning, silt removal, and stormwater channel management. The quiet, emission-free operation makes them well-suited for urban or coastal zones where traditional fuel-based systems pose logistical or environmental challenges.

In industrial ponds and lagoons, electric pumps deliver consistent sludge management and environmental restoration performance. Their automated control systems allow precise sediment removal without disrupting ongoing industrial activity.

Celtic Pumps’ portfolio includes successful deployments in port maintenance, mineral recovery, and wastewater management projects across Asia and the Middle East. In each case, clients have achieved measurable improvements in operational efficiency, reduced energy use, and extended service life—demonstrating how electric dredging technology can transform both performance and sustainability outcomes.

Choosing the Right Electric Dredge Pump for Your Operation

Selecting the right electric dredge pump requires a careful evaluation of several operational parameters to ensure maximum performance and efficiency. Key considerations include the desired flow rate, total dynamic head, slurry density, available power supply, and duty cycle. Each of these factors directly impacts how effectively the electric dredge pump handles varying material loads and operating conditions. For example, higher slurry density demands a stronger impeller design and wear-resistant materials, while variations in head and flow rate influence the selection of motor power and impeller geometry. Matching these parameters accurately ensures the electric dredge pump operates at peak efficiency with minimal energy loss.

Customization plays a crucial role in achieving optimal performance and extending the life of an electric dredge pump. A tailored design can adapt to specific site conditions—whether it’s fine silt, sand, or abrasive gravel—allowing the electric dredge pump to deliver consistent suction and discharge performance without overloading the motor or increasing wear. This adaptability is particularly important in large-scale industrial applications where the dredge pump electric system must operate continuously under demanding environments.

Equally important is after-sales service and technical support, which directly influence the reliability of an electric dredge pump over its operational lifespan. Even the most durable electric dredge pump benefits from regular monitoring, calibration, and timely replacement of wear components to maintain consistent performance. Celtic’s approach focuses on engineering precision and long-term dependability, ensuring each electric dredge pump is built to handle real-world challenges efficiently.

By combining advanced material engineering, precise hydraulic design, and dedicated customer support, Celtic ensures that every dredge pump electric system delivers measurable results. Each electric dredge pump is engineered not only for power and endurance but also for operational stability—helping clients achieve lower downtime, predictable performance, and superior energy efficiency in every dredging application.

Balancing Performance, Profitability, and Sustainability in Modern Dredging

The dredge pump electric system has redefined how industries approach modern dredging—offering a powerful combination of operational precision, financial efficiency, and environmental responsibility. Its direct-drive mechanism eliminates unnecessary energy losses, ensuring stable flow control and consistent performance under varying loads. This reliability enhances productivity in demanding conditions such as mining tailings, harbor dredging, and offshore slurry transport, where uptime and accuracy are critical.

From a financial standpoint, understanding the electric dredge pump price requires a long-term perspective. While the upfront electric dredge pump price may exceed that of diesel-driven alternatives, the savings achieved through reduced fuel usage, lower maintenance costs, and extended equipment life deliver a significantly higher return on investment. Industries that have adopted this technology often find that the electric dredge pump price pays for itself through operational savings within a short span. Moreover, the electric dredge pump price reflects superior engineering quality, longer service intervals, and minimized downtime—factors that directly contribute to lower total cost of ownership.

In addition, the electric dredge pump price represents not just a capital expense but a sustainability investment. Electric systems operate with zero direct emissions and minimal noise, ensuring compliance with tightening environmental standards. This makes the dredge pump electric solution especially valuable for ports, municipalities, and industries integrating green initiatives into their operational frameworks.

The electric dredge pump price also correlates with the technology’s adaptability—offering customization options for flow capacity, head requirements, and slurry composition. Such flexibility allows operators to tailor performance precisely to project conditions, maximizing energy efficiency and output. The electric dredge pump price thus becomes a measure of long-term resilience, energy economy, and operational stability rather than a simple purchase figure.

As industries prioritize reliability, cost control, and environmental compliance, the dredge pump electric model stands as a future-ready investment that delivers measurable advantages across every performance metric. Explore Celtic’s range of dredge pump electric systems engineered for long-term performance and measurable results, designed to meet the evolving needs of modern dredging and slurry transport operations.