In industrial and dredging applications, mud pumping plays a crucial role in transferring mixtures of liquids and solids, often under challenging conditions. These slurries can range from simple water-based mixtures to highly abrasive or viscous substances, making it essential to select the right pump for the job. Industries such as mining, construction, and dredging rely heavily on sludge pumps to ensure efficient material transport, minimizing downtime and maximizing productivity.

Choosing the right pump is key to ensuring operational efficiency and reducing costs. A properly selected pump can improve the performance of slurry systems, reduce energy consumption, and extend the lifespan of equipment. In contrast, using the wrong type of pump can lead to frequent maintenance, higher energy bills, and even premature pump failure, all of which drive up project costs.

For many projects, slurry pump rental offers a flexible solution, particularly when the pump is needed for a short-term project or if specialized equipment is required. It allows businesses to access high-quality pumps without the long-term investment. Partnering with reliable slurry pump suppliers is also crucial, as they can provide expert guidance, after-sales service, and the right equipment for each unique project. Their support can make all the difference in ensuring smooth operations and project success.

Understanding Slurry and Its Challenges

Slurry is a mixture of solid particles and liquids that are often difficult to manage due to their unique characteristics. In most industrial applications, slurry is a dense, viscous fluid that can contain various types of solids suspended in water or other liquids. These mixtures can range from relatively low-solids content slurries in wastewater treatment plants to highly abrasive or corrosive slurries found in mining, dredging, and construction operations. Slurry composition is typically defined by the particle size, shape, and concentration of solids, as well as the properties of the liquid component. This combination of solids and liquids creates distinct challenges that must be addressed when selecting and maintaining mud pumps.

Several industries rely on effective slurry management for efficient operations. In the mining sector, slurries are generated during mineral extraction and processing, requiring robust mud pumps to handle abrasive materials like sand, rocks, and ores. Similarly, in dredging, slurry is produced during the removal of sediment from waterways, which requires specialized pumps to transport dense mixtures of sand, mud, and water over long distances. In construction, particularly in tunneling or excavation projects, slurry is often used as a cooling and lubrication medium for drilling operations, where consistency and flow rate are critical. The oil and gas industry also generates slurry, particularly in offshore drilling, where slurries are used in mud systems to support drilling operations and maintain pressure control.

Slurry management presents a number of key challenges. One of the most significant is high abrasiveness, especially in mining or dredging slurries. The solid particles can cause rapid wear on equipment, leading to maintenance challenges and high operational costs. Viscosity is another challenge, as highly viscous slurries require pumps that can move thick, sticky fluids without clogging or causing excessive wear. Finally, sedimentation is a common issue, especially in slurries with a high concentration of fine particles. As slurries settle, the solids can create blockages and cause pump failure if not properly managed.

In such demanding conditions, working with reliable slurry pump suppliers is essential for obtaining the right equipment. These suppliers offer pumps that are specifically designed to handle the challenges of slurry transport and provide expert advice on maintenance and performance optimization. For temporary projects or specific needs, slurry pump rental is also a viable option, offering flexibility without the commitment of purchasing expensive equipment. By partnering with experienced slurry pump suppliers, businesses can ensure their slurry systems are optimized for efficiency, minimizing downtime and maximizing productivity.

Types of Slurry Pumps and Their Applications

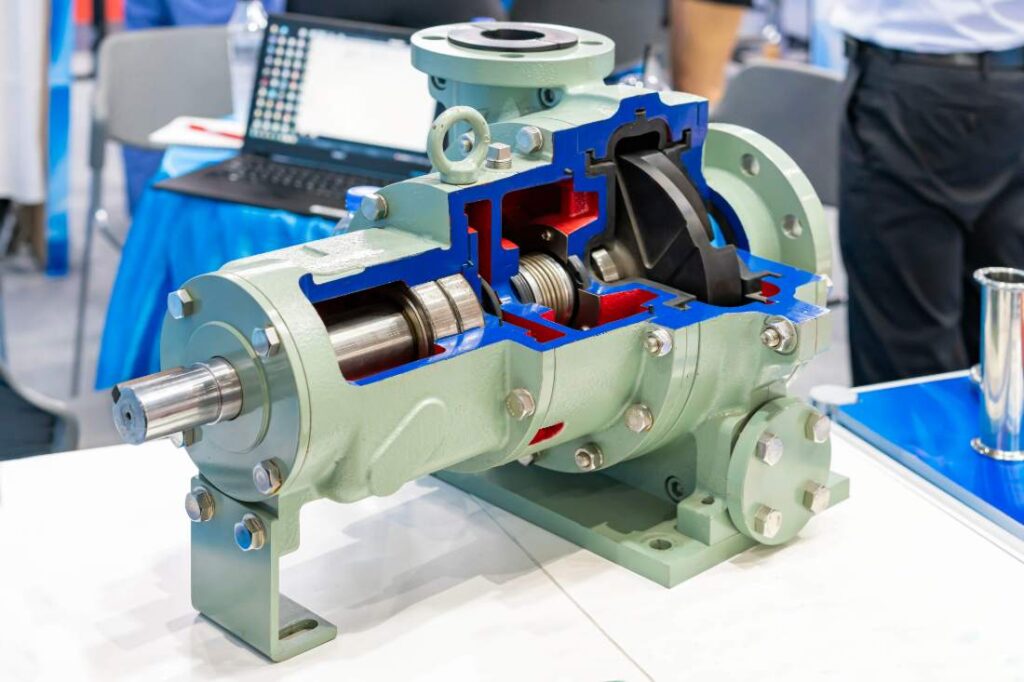

Centrifugal Slurry Pumps

Centrifugal sludge pumps are the most commonly used type in industries dealing with abrasive or high-solids-content slurries. These pumps rely on centrifugal force to move the slurry through the pump casing, making them highly efficient in transferring large volumes of slurry over long distances. Centrifugal pumps are ideal for applications where the slurry has a moderate to high flow rate and relatively low viscosity, such as in mining and dredging. However, their effectiveness can be impacted by the abrasiveness of the slurry, requiring pumps with wear-resistant materials.

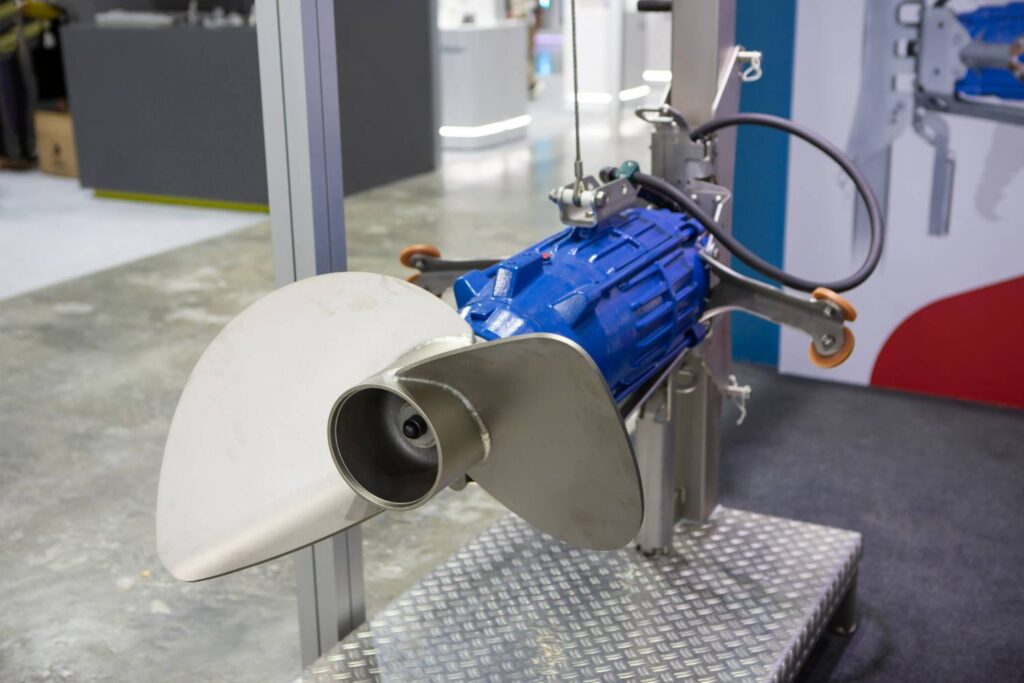

Submersible Slurry Pumps

Submersible slurry pumps are designed to operate while submerged in the slurry itself. These pumps are commonly used in environments where the slurry is being pumped from a submerged location, such as dredging operations or wastewater treatment plants. Submersible pumps are highly efficient in handling slurries with varying levels of viscosity and solids content, and they excel in situations where a centrifugal pump would be less effective. These pumps are often preferred for confined spaces and deep-set applications.

Horizontal vs. Vertical Slurry Pumps

The choice between horizontal vs. vertical sludge pumps largely depends on the installation environment and the specific needs of the project. Horizontal mud pumps are typically easier to maintain and install, making them ideal for applications with a horizontal slurry flow path, such as in open-pit mining or sediment removal projects. On the other hand, vertical mud pumps are well-suited for submerged applications and can handle slurries with a high solids concentration. Vertical pumps are commonly used in dredging operations or deep sumps.

Working with trusted slurry pump suppliers can help ensure the right pump selection. These suppliers have the expertise to match the appropriate pump with the project’s specific needs, whether it’s for high-abrasive slurries or low-flow applications. In some cases, slurry pump rental is an excellent option, especially when specialized pumps are required for a short-term project or pilot study. By renting pumps, businesses can test various models to find the best fit for the job without making a significant capital investment. Reliable slurry pump suppliers can also assist in providing rental solutions that meet specific project demands.

Key Factors to Consider When Choosing a Slurry Pump

When selecting the right mud pump for a project, several key factors need to be considered to ensure efficiency and cost-effectiveness. These factors revolve around slurry characteristics, pump performance requirements, material construction, operating environment, and budget. Understanding these elements helps to avoid operational inefficiencies, reduce maintenance costs, and improve the overall pump lifespan.

For projects that require flexibility or have short-term needs, slurry pump rental can be a viable option. Renting a pump allows businesses to test different models and configurations without committing to a large capital investment. This flexibility can be especially valuable when facing specific or temporary project requirements that might not justify the purchase of a pump.

Slurry Characteristics

The composition of the slurry plays a significant role in determining which pump will perform best. Particle size and shape influence how easily the slurry flows through the pump. Larger or irregularly shaped particles, for instance, may require pumps with larger clearances or special impeller designs. Solids concentration is another critical factor—high solid content increases the wear on the pump and requires pumps designed to handle abrasive materials. Lastly, the viscosity and pH levels of the slurry must be considered, as thick, viscous slurries require powerful pumps with specific flow capabilities. In contrast, extreme pH levels may call for corrosion-resistant materials.

Pump Performance Requirements

To ensure that the mud pump meets the demands of the application, flow rate (GPM) and total dynamic head (TDH) are essential performance parameters. Flow rate determines how much slurry can be moved in a given time, while TDH measures the pump’s ability to overcome friction and elevation changes in the system. Additionally, evaluating efficiency curves and power consumption is important to avoid energy waste and ensure that the pump can deliver the required output without excessive costs.

Material Construction

The importance of wear-resistant materials like high-chrome or rubber-lined components cannot be overstated when selecting mud pumps. These materials reduce the risk of pump damage in highly abrasive slurries, extending the life of the equipment. Similarly, selecting materials based on slurry abrasiveness and corrosiveness helps prevent premature failure and ensures the pump can withstand harsh operating conditions.

Operating Environment

The pump’s operating environment is another major factor. Temperature, altitude, and pressure conditions can all impact the pump’s performance, so it’s vital to choose a pump designed for these specific conditions. Additionally, portability and ease of maintenance are crucial for projects requiring frequent movement or maintenance, especially when choosing between submersible vs. dry-installed pumps.

Budget and Project Duration

Finally, businesses need to evaluate the best option for their budget and project duration. For short-term or project-specific needs, slurry pump rental can be an ideal solution, offering flexibility without long-term commitment. However, for long-term use, purchasing might be more cost-effective. Consulting with experienced slurry pump suppliers can help businesses assess whether to rent or purchase based on their needs, ensuring the right decision is made for the project’s scope and budget.

The Role of Slurry Pump Suppliers

When choosing the right pump for your project, partnering with reputable slurry pump suppliers is essential to ensuring that you receive high-quality products and expert support. A trusted supplier will not only provide the appropriate pumps but also offer a range of services to ensure that your slurry management systems operate efficiently and effectively. Here’s how to identify the right slurry pump supplier and why their services matter.

How to Identify Reputable Slurry Pump Suppliers

Reputable slurry pump suppliers are characterized by their experience, expertise, and industry reputation. Look for suppliers with a proven track record in the mud pump market, particularly in the specific industry you’re operating in—whether that’s mining, dredging, or construction. A well-established supplier should have an extensive portfolio of products suited to various slurry types, from abrasive to corrosive mixtures. Additionally, positive customer reviews and case studies can provide insights into their reliability and the performance of their equipment in real-world applications. For projects requiring flexibility, slurry pump rental can be a great option, allowing you to test different pumps and determine which best fits your needs before making a long-term commitment. By choosing a reputable supplier, you ensure access to high-quality equipment, whether you’re purchasing or renting, and reliable support throughout the project.

Value-Added Services: Custom Engineering, Technical Support, Spare Parts Availability

A key differentiator for top-tier slurry pump suppliers is their ability to offer value-added services. These include custom engineering, where the supplier tailors the pump design to fit the unique needs of your project. Whether it’s modifying the pump to handle specific slurry characteristics or designing a more efficient system, a good supplier will have engineering capabilities that go beyond just providing standard equipment. This can be especially important when you require specialized solutions that are not available off the shelf, and slurry pump rental can help in such cases by allowing access to customized equipment for specific project needs.

Technical support is another crucial service provided by reputable suppliers. With technical knowledge at hand, they can assist with pump selection, installation, and troubleshooting, ensuring the system runs smoothly. This can be particularly beneficial when you’re dealing with complex slurry mixtures or challenging conditions. Furthermore, spare parts availability is critical, as pumps need regular maintenance and occasional replacement parts to ensure uninterrupted operation. A supplier with a comprehensive inventory of spare parts can minimize downtime and keep operations running smoothly. For short-term projects, slurry pump rental also allows you to access high-quality pumps without the long-term commitment, ensuring you have the right equipment at the right time.

Importance of After-Sales Service and Support

After-sales service and support are fundamental to the longevity and efficiency of your sludge pumping system. Reliable slurry pump suppliers will offer ongoing support to ensure that your pumps perform optimally throughout their lifespan. This includes routine maintenance, performance checks, and troubleshooting advice to prevent potential failures. Additionally, for businesses that require slurry pump rentals, choosing a supplier who offers prompt and efficient after-sales service ensures that rented pumps are properly maintained and supported throughout the rental period. This can reduce downtime and keep your project on schedule.

In summary, a reputable slurry pump supplier does more than just sell equipment—they are an integral partner in ensuring the success of your slurry management project. By selecting a supplier that offers comprehensive services, you can ensure that your pumping systems are efficient, cost-effective, and reliable throughout the project’s duration.

Conclusion and Final Recommendations

In conclusion, selecting the right pump requires careful consideration of several key factors, including slurry characteristics, pump performance requirements, material construction, and operating environment. Understanding these elements ensures you choose a pump that meets the specific needs of your project, whether it’s for handling abrasive, high-viscosity slurries or for working under challenging environmental conditions.

Partnering with expert slurry pump suppliers is crucial for ensuring you have access to high-quality, reliable pumps and value-added services like technical support and custom engineering. For projects with short-term needs, slurry pump rental offers flexibility without the long-term financial commitment, allowing businesses to use specialized equipment as needed.

Finally, always consult with professionals who have experience in sludge pump systems. Their expertise can guide you in making informed decisions, ensuring long-term operational efficiency, and minimizing risks associated with pump failure or inefficient performance. By making the right choice upfront, you can achieve smooth, cost-effective slurry management throughout the project lifecycle.